- Summary

-

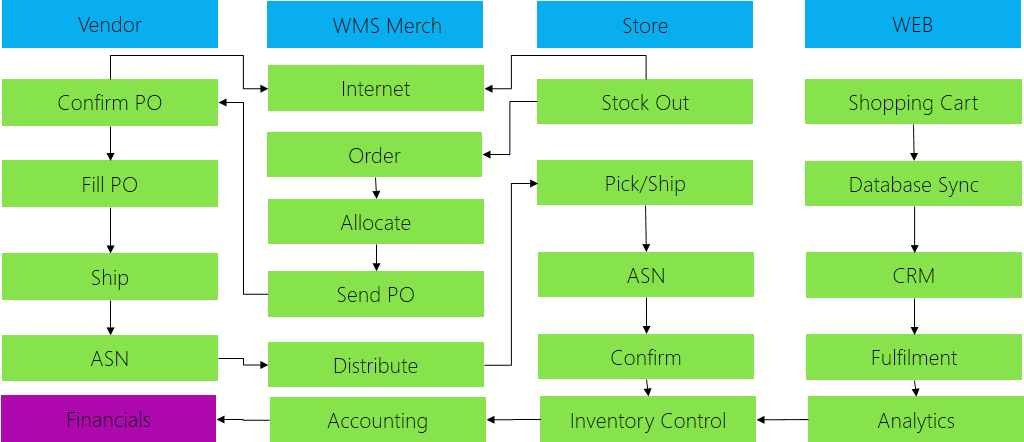

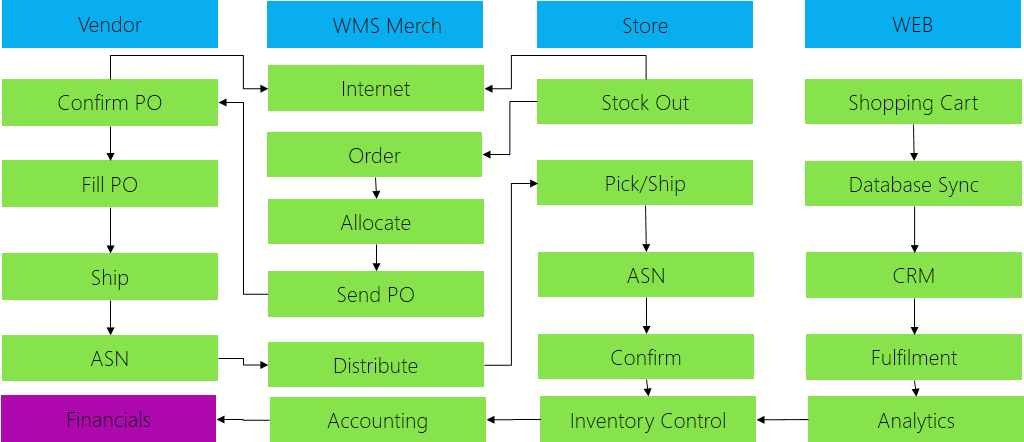

Supply chain management is the key to having the right product in the right place at the right time.

The objective for Cybex Logistics Management system is to maximize turnover and in-stock positions while minimizing inventory levels and operational costs.

This is achieved by enhancing the decision process with timely actionable information and flexible execution systems necessary for adapting to changing retail market conditions.

Cybex Retail Warehouse Management provides all the tools necessary for efficiently managing and controlling stock allocation, automated replenishment, inventory consolidation and distribution centers.

Provides the functional flexibility, and timely accurate information you need for consistently managing and improving distribution operations.

The results are improved in-stock levels, reduced inventory and lead-times, increased turnover, and reduced labor costs.

Cross-docking, flow-through, and stock to DC Reduces handling and replenishment lead-times, both pre-receipt and post-receipt allocated flow-through, providing visibility into cross-docked and stock merchandise.

-

Benefits

-

Operations management:

Provides management with insight into distribution trends, costs, and performance.

Labor management:

Puts timely information into the hands of warehouse operators, with powerful labor reporting that combines user defined labor specifications and standards for all warehouse activities

Distribution and Resource Planning:

Better resource planning, along with increased productivity, decreases labor costs

Improved space utilization:

Optimizing physical space usage reduces distribution center operating constraints

Reduced inventory:

Efficient product flow helps cut down on excess inventory

Value-added services:

Provides user defined, value-added service functionality, including the automatic routing of service merchandise, paperless tracking of activity and costs, and definition of radio-frequency task queue for visibility and management

Style maintenance and profiling:

Provides the ability to manage slotting of items to ensure proper placement and pick utilization

Receiving and Stocking Units, Lot Size and Pre-Packs:

Enhances efficient warehouse package handling and stock consolidation by merchandise group

- Features

-

Full Advance Shipment Notification functionality

Provides the ability to receive advance shipment notification to ensure accuracy and improve receiving efficiencies

Receiving and pre-distribution with inbound processing

Supports the ability to receive inbound receipt information with allocation information to improve merchandise movement

Mobile Wireless Applications

Manages merchandise in the distribution center via module-containing system and radio-frequency screens for general inventory functions, directed put-away, and movement of inventory, inventory adjustments, returns processing, and cycle counting

Wireless hand-held Barcode scanner terminals

Enhances communications with inventory control office and provides real-time connectivity for maximum efficiency and DC activity monitoring